Aqualon ethylcellulose Chemistry: Cellulosics

Price 100 INR/ Piece

Aqualon ethylcellulose Chemistry: Cellulosics Specification

- Molecular Weight

- Varies, typically 44,000124,000 g/mol

- Size

- Custom sizes available

- Usage

- Binder, film former, viscosifier

- Melting Point

- Not applicable, thermoplastic

- Ph Level

- Neutral

- Physical State

- Solid

- Storage Instructions

- Store in dry, cool place

- Density

- 1.12 Gram per cubic centimeter(g/cm3)

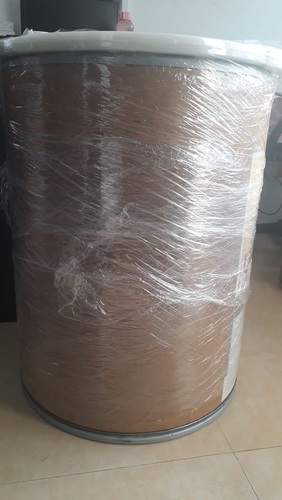

- Packaging Type

- Bag or Drum

- CAS No

- 9004-57-3

- Molecular Formula

- (C6H7O2(OR)3)n

- Shelf Life

- 24 months

- Flash Point

- Not flammable

- Purity

- 99%

- Grade

- Industrial Grade

- Type

- Cellulosic Polymer

- Application

- Pharmaceuticals, coatings, food additive, inks

- Appearance

- White to off-white powder

- Purity(%)

- 99%

- Transparency

- Clear film forming

- Viscosity

- Varies, typically 10300 cps (5% solution, ethanol/ethyl acetate)

- Color

- White to light yellow powder

- Moisture Content

- < 3%

- Stability

- Stable under normal conditions

- Heavy Metals

- < 10 ppm

- Odor

- Odorless

- Particle Size

- 80120 mesh

- Toxicity

- Non-toxic

- Lead Content

- < 2 ppm

- Solubility

- Soluble in organic solvents, insoluble in water

- Substitution Type

- Ethyl substitution degree: 4548%

- Regulatory Compliance

- FDA approved as food additive

Aqualon ethylcellulose Chemistry: Cellulosics Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 3 Pieces Per Week

- Delivery Time

- 3-4 Week

- Main Export Market(s)

- Australia, South America, Middle East, Central America, Asia, Western Europe, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Aqualon ethylcellulose Chemistry: Cellulosics

Chemistry: Cellulosics

Aqualon ethylcellulose (EC) is a cellulose ether distinguished by its versatility.

Aqualon EC N-200 PC is an oil/organic solvent dispersible film former and thickener. This thickener and film former is typically used in anhydrous formulations, such as sunscreen oils, make-up removers, and color cosmetics. In color cosmetics formulations, this film former imparts shine,improves wear, and increases color brightness.

Features and Benefits

- Film former

- Thickener

Outstanding Film-Forming Properties

Aqualon ethylcellulose stands out for its ability to create clear, strong films, enhancing the performance of coatings, pharmaceutical tablets, and ink formulations. Its transparency and consistent quality ensure reliable results across various industrial applications. This characteristic also contributes to its popularity as a protective and moisture-resistant agent in food and pharmaceutical products.

Regulatory Compliance and Safety

This ethylcellulose meets strict safety standards, including FDA approval for use as a food additive. Its non-toxic nature, extremely low levels of heavy metals, and 99% purity make it a trusted choice for applications requiring stringent quality controls. Users benefit from peace of mind knowing it is safe and stable when handled and stored correctly.

FAQ's of Aqualon ethylcellulose Chemistry: Cellulosics:

Q: How should Aqualon ethylcellulose be stored to maintain its quality?

A: To preserve the product's integrity, store Aqualon ethylcellulose in a dry, cool environment within sealed bags or drums. Avoid moisture exposure, as its low moisture content (<3%) is crucial for performance. Proper storage extends the shelf life up to 24 months.Q: What are the primary uses of Aqualon ethylcellulose in industry?

A: Aqualon ethylcellulose serves as a binder, film former, and viscosifier in various sectors, including pharmaceuticals (as a tablet coating), food additives (for moisture resistance), coatings, and printing inks. Its versatility comes from its excellent solubility in organic solvents and clear film-forming properties.Q: When is Aqualon ethylcellulose preferred over other cellulosic polymers?

A: It is chosen when water-insoluble films, high purity, and FDA compliance are required, as in pharmaceutical coatings or moisture-resistant food products. Its stability and non-toxic profile make it suitable for sensitive applications where safety and regulatory standards are paramount.Q: Where can Aqualon ethylcellulose be obtained, and what packaging options are available?

A: Aqualon ethylcellulose can be sourced from suppliers and traders throughout India. It is typically packaged in bags or drums, with custom sizes available to meet specific industrial needs.Q: What is the process for utilizing Aqualon ethylcellulose in a formulation?

A: To use Aqualon ethylcellulose, dissolve the required quantity in a suitable organic solvent (such as ethanol or ethyl acetate). Once fully dissolved, incorporate the solution into your formulation as a binder, film former, or viscosifier, depending on application requirements.Q: What are the benefits of using Aqualon ethylcellulose in food and pharmaceutical products?

A: The principal benefits include creating clear, protective films that resist moisture, extending product shelf life. Its non-toxic, FDA-approved status and negligible heavy metal content further enhance its suitability for products with strict regulatory requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oral Solid Dosage Form Category

AquaSolve Hypromellose Acetate Succinate (HPMCAS)

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Pharmaceutical Grade

Purity(%) : 99%

Appearance : White to offwhite powder

Type : Other, Polymer / Excipient

Natrosol Hydroxyethylcellulose

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Industrial Grade

Purity(%) : 99%

Appearance : White or offwhite powder

Type : Other, Thickener

Plasdone Povidone

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Pharmaceutical Grade

Purity(%) : 99%

Appearance : White to offwhite powder

Type : Other, Polyvinylpyrrolidone

Aquarius film coating systems Chemistry: Film Coating Systems

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Pharmaceutical Grade

Purity(%) : >99%

Appearance : Offwhite to light yellow powder

Type : Other, Film Coating System

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free