Zirconium (Sn-Fe-Cr) alloy

Zirconium (Sn-Fe-Cr) alloy Specification

- Purity

- 99%

- Molecular Formula

- Zr

- Usage

- Zirconium is very resistant to corrosion by many common acids and alkalis and by sea water. It is therefore used extensively by the chemical industry where corrosive agents are employed. The metal is used as an alloying agent in steel and for making surgical appliances.

- Molecular Weight

- 91.22 Grams (g)

- Melting Point

- 1,855 °C

Zirconium (Sn-Fe-Cr) alloy Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 500 Kilograms kg Per Month

- Delivery Time

- 2-8 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Carton and Poly Bag.

- Main Export Market(s)

- South America, Western Europe, Australia, Central America, Africa, Middle East, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Zirconium (Sn-Fe-Cr) alloy

FAQs of Zirconium (Sn-Fe-Cr) alloy:

Q: What is the key advantage of Zirconium (Sn-Fe-Cr) alloy in industrial usage?

A: Zirconium alloy is highly resistant to corrosion, making it ideal for industries involving exposure to acids, alkalis, and seawater.Q: What are the primary applications of this material?

A: It is used in the chemical industry, steel alloy production, and for manufacturing surgical appliances.Q: What is the melting point of Zirconium (Sn-Fe-Cr) alloy?

A: The alloy has a melting point of 1,855C.Q: What is the molecular weight of this alloy?

A: The molecular weight of Zirconium alloy is 91.22 grams.Q: Why is this alloy preferred in surgical appliance manufacturing?

A: Its corrosion resistance and high durability make it suitable for reliable and long-term use in medical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Analytical Grade Chemicals Category

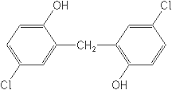

Dichlorophene

Price 100 INR

Minimum Order Quantity : 1 Kilograms

Molecular Formula : C13H10Cl2O2

Appearance : white or offwhite powder

Molecular Weight : 269.12 Grams (g)

Melting Point : 177.5 °C

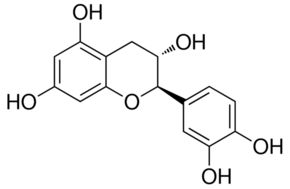

(+)-Catechin

Price 100 INR

Minimum Order Quantity : 1 Kilograms

Molecular Formula : C15H14O6

Appearance : Colorless solid

Molecular Weight : 290.26 Grams (g)

Melting Point : 175 °C

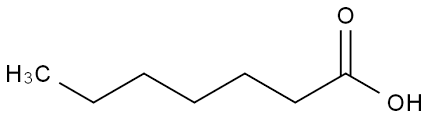

Heptanoic acid

Price 100 INR

Minimum Order Quantity : 1 Kilograms

Molecular Formula : C7H14O2

Appearance : Oily liquid

Melting Point : −7.5 °C (18.5 °F; 265.6 K)

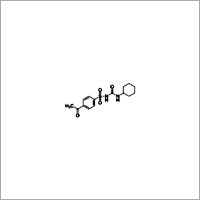

Acetohexamide

Price 100 INR

Minimum Order Quantity : 1 Kilograms

Molecular Formula : C15H20N2O4S

Appearance : White to OffWhite Solid

Molecular Weight : 324.395 Grams (g)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free