Cavitron and CAVASOL* hydroxypropyl-- and hydroxypropyl--cyclodextrins (HPBCD and HPGCD)

Cavitron and CAVASOL* hydroxypropyl-- and hydroxypropyl--cyclodextrins (HPBCD and HPGCD) Specification

- Molecular Formula

- (C42H70-nO35(C3H6O)n) (HPBCD); (C48H80-nO40(C3H6O)n) (HPGCD)

- CAS No

- 128446-35-5 (HPBCD), 128446-36-6 (HPGCD)

- Physical State

- Solid

- Storage Instructions

- Store in a cool, dry, and well-ventilated place, tightly closed

- Purity

- >98%

- Melting Point

- Decomposes above 280C

- Size

- Customized as per requirement

- Density

- 0.60 Gram per cubic centimeter(g/cm3)

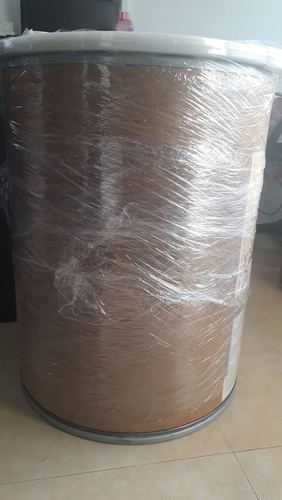

- Packaging Type

- HDPE drums, PE bags, Customized packaging

- Ph Level

- 5.0 - 8.0 (1% aqueous solution)

- Shelf Life

- 24 months

- Usage

- Solubilizing agent, excipient, stabilizer

- Molecular Weight

- 1380 (HPBCD), 1550 (HPGCD)

- Grade

- Pharmaceutical Grade

- Type

- Hydroxypropyl--cyclodextrin (HPBCD) and Hydroxypropyl--cyclodextrin (HPGCD)

- Application

- Pharmaceutical, food, cosmetics, analytical reagent

- Appearance

- White to off-white, amorphous powder

- Purity(%)

- >98%

Cavitron and CAVASOL* hydroxypropyl-- and hydroxypropyl--cyclodextrins (HPBCD and HPGCD) Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

About Cavitron and CAVASOL* hydroxypropyl-- and hydroxypropyl--cyclodextrins (HPBCD and HPGCD)

CavitronAAA and CAVASOL* hydroxypropyl-AA- and hydroxypropyl-AA3-cyclodextrins (HPBCD and HPGCD)

Chemistry: Cyclodextrins

The molecular structure of cyclodextrins creates a bucket-like cavity that can function to complex with molecules or functional groups on molecules. The substitution of hydroxyl groups on native cyclodextrins to make hydroxypropyl-AA- or hydroxypropyl-AA3-cyclodextrins (HPBCD or HBGCD) significantly enhances their solubility and makes them more suitable for drug solubilization. This mechanism makes the Cavitron and CAVASOL HPBCDs and HPGCDs capable of masking unpleasant taste/odor and stabilizing drugs that are prone to degradation, and also can increase solubility of poorly soluble compounds in oral drug delivery systems. Purification of the Cavitron cyclodextrins to remove endotoxins allows their use for solubilization of drugs for parenteral drug products.

Exceptional Solubility and Purity

Cavitron and CAVASOL* HPBCD and HPGCD dissolve readily in water, making them highly effective for improving the solubility of poorly soluble compounds. They are manufactured to surpass 98% purity, ensuring both efficacy and safety in sensitive pharmaceutical, food, and cosmetic applications. Their odorless and stable profile complements diverse formulation needs while maintaining product quality.

Regulatory Compliance and Safety

These cyclodextrins comply with Ph. Eur., USP, and ICH standards, ensuring low levels of impurities such as heavy metals and endotoxins. With bacterial endotoxins below 0.25 EU/mg and heavy metals under 10 ppm, these materials are exceptionally safe for end-product use. Pharmaceutical-grade quality and proper identification protocols further reinforce reliability.

Versatile Applications Across Industries

HPBCD and HPGCD serve as solubilizing agents, excipients, stabilizers, and analytical reagents, benefiting pharmaceutical, food, and cosmetic industries alike. Their high stability, customizable packaging, and adaptable particle size enable convenient integration into different formulations, tools, and production environments.

FAQ's of Cavitron and CAVASOL* hydroxypropyl-A- and hydroxypropyl-AA3-cyclodextrins (HPBCD and HPGCD):

Q: How do Cavitron and CAVASOL* cyclodextrins improve solubility in formulations?

A: Cavitron and CAVASOL* HPBCD and HPGCD significantly enhance the solubility of poorly water-soluble substances by forming inclusion complexes. These complexes can increase the bioavailability, stability, and dispersibility of active ingredients in pharmaceutical, food, and cosmetic formulations.Q: What grade and purity are Cavitron and CAVASOL* HPBCD and HPGCD?

A: Both products are pharmaceutical grade with a purity exceeding 98%. This ensures suitability for sensitive formulations in pharmaceuticals, foods, and cosmetics, meeting stringent international standards (Ph. Eur., USP, and ICH guidelines).Q: When should these cyclodextrins be used in a formulation process?

A: They should be incorporated during the formulation stage whenever there is a need to improve solubility, stability, or taste-masking properties of active compounds. Their use is particularly important for hydrophobic substances to increase efficacy and shelf-life.Q: Where are these cyclodextrins typically applied?

A: HPBCD and HPGCD are widely applied in pharmaceuticals (as solubilizers and stabilizers), the food industry (as carriers or flavor protectors), cosmetics (to stabilize and solubilize active ingredients), and for analytical purposes as reagents.Q: What are the benefits of using HPBCD and HPGCD over regular cyclodextrins?

A: Hydroxypropyl substitution enhances water solubility and safety profile compared to native cyclodextrins, providing better encapsulation efficiency, lower toxicity, and broader compatibility across diverse formulation matrices.Q: How should Cavitron and CAVASOL* cyclodextrins be stored and handled?

A: They should be stored in a tightly closed container within a cool, dry, and well-ventilated area to maintain their stability and prolong shelf life (up to 24 months). Packaging options include HDPE drums and PE bags, with customization available based on requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Parenteral Dosage Form Category

Aqualon Sodium Carboxymethylcellulose Chemistry: Cellulosics

Molecular Weight : Varies by grade, typically 90,000 700,000 g/mol

Type : Other, Sodium Carboxymethylcellulose

Application : Used in food, pharmaceutical, textile, paper, and detergent industries

Usage : Thickening agent, stabilizer, binder, rheology modifier

Ph Level : 6.5 8.5 (1% solution)

Purity(%) : 99%

Pharmasolve N-methyl-2-pyrrolidone

Molecular Weight : 99.13 g/mol

Type : Other, Solvent

Application : Used as solvent in pharmaceutical formulations

Usage : Pharmaceutical excipient, solvent for APIs

Ph Level : Neutral

Purity(%) : 99.9%

Plasdone povidone C grades

Molecular Weight : Varies by grade (approx. 10,000700,000)

Type : Other, Povidone Polymer

Application : Pharmaceutical, cosmetic, industrial uses

Usage : Filmforming agent, binder, stabilizer

Ph Level : 3.0 7.0

Purity(%) : >99.0

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free